Modern Transformer Production Center

We continue our electrical transformer production journey, which we started as Deniz Elektrik in 2006, with our AGT Transformator identity since 2021. We offer our 17 years of experience in the electrical sector with transformer production, transformer sales and transformer maintenance services.

AGT Transformator: Quality and Expertise

AGT Transformator was established in Şanlıurfa to operate in the field of electrical machine production. We continue our electrical transformer production journey, which we started as Deniz Elektrik in 2006, with our new identity since 2021. Our company, which set out with the philosophy of 'Quality is the Key to Every Door', stands out in the sector with its expert team and technical equipment in transformer production, maintenance and repair. We serve in an area of 14,000 m² in our modern production facilities.

- High Quality Material Usage

- Experienced Engineer and Technician Staff

- Production in Accordance with International Standards

- Environmentally Friendly and Sustainable Production Approach

- 17 Years of Sector Experience

AGT Transformator's Journey

Continuous development in electrical transformer production from 2006 to present

Foundation

We started operating in the electrical sector as Deniz Elektrik

Production Start

We performed our first transformer production

New Identity

New era with AGT Transformator name

17th Year

17 years of experience in the electrical sector

Transformer Production Stages

At AGT Transformator, every product is produced with carefully planned steps supported by modern technology. As a factory producing electrical transformers, we continuously improve our quality standards.

Magnetic Circuit (Core)

High quality magnetic sheets are cut in special machines to form the core of the transformer. Precise tolerances are observed for energy efficiency.

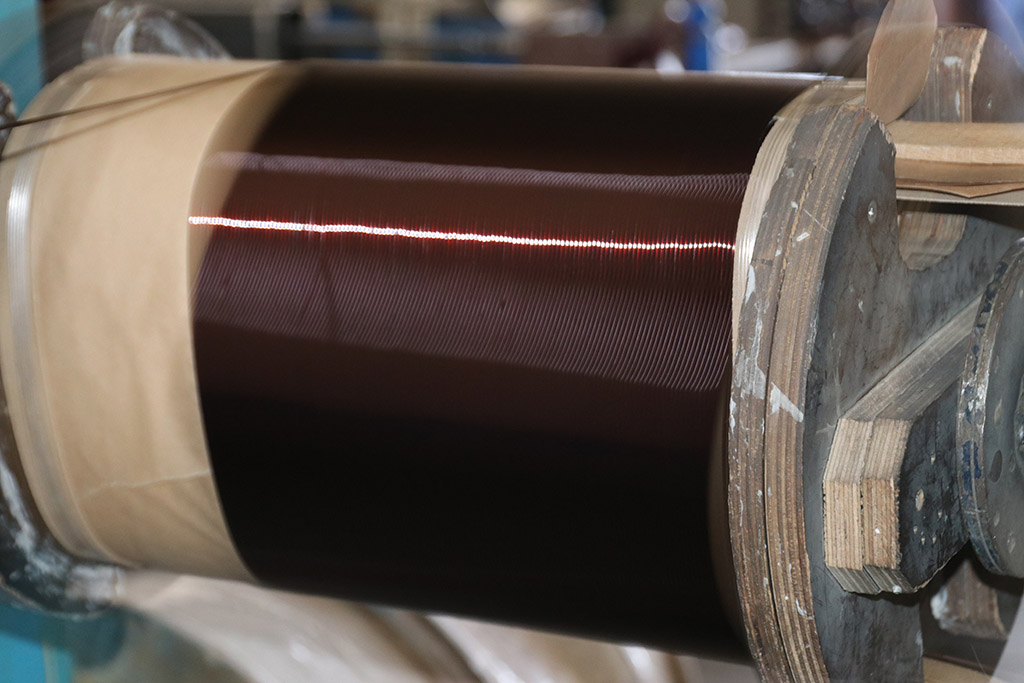

Winding Process

Copper or aluminum conductors are wound in modern winding machines in accordance with voltage and insulation standards. This stage determines the electrical performance of the transformer.

Active Part Assembly

Wound coils and magnetic core are brought together to form the active part of the transformer. Connections are made carefully and insulation tests are performed.

Tank and Cover Production

The tank and cover, which are the outer housing of the transformer, are produced from high-strength steel materials. It provides sealing and protection against environmental effects.

Painting Process

Tank and cover are painted with special paint and coating techniques to provide long-lasting protection against external factors. This process increases durability and provides aesthetic appearance.

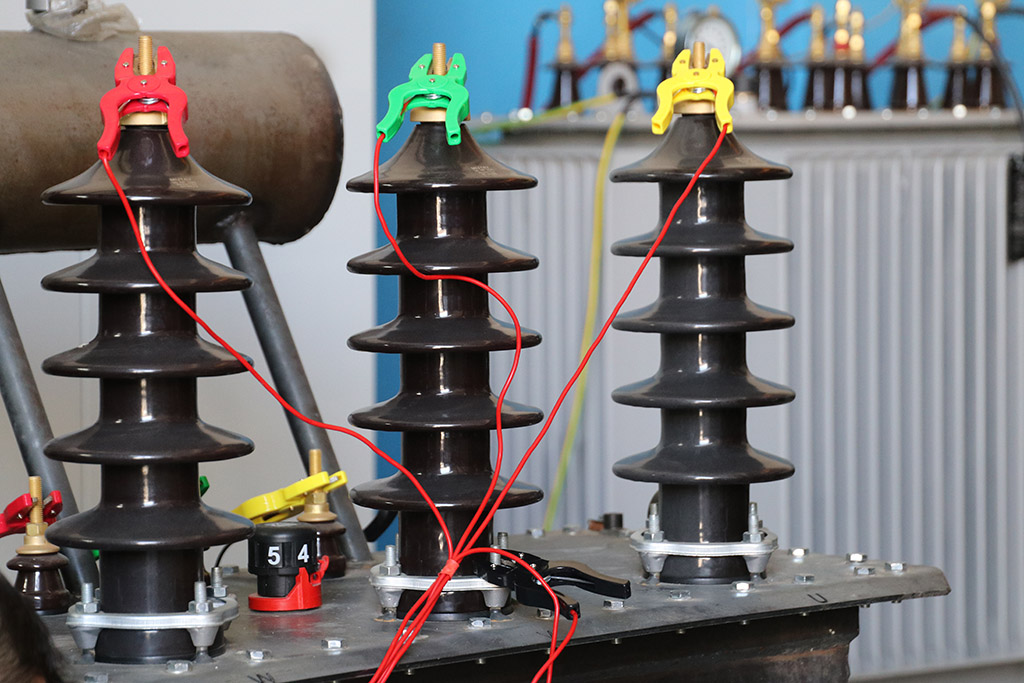

Final Assembly and Connections

After all main components are brought together, electrical connections, insulators and other accessories are mounted. This stage is the last stop of quality control.

Comprehensive Transformer Services

We offer comprehensive solutions in electrical transformer production

Transformer Production

Transformer production in power ranges of 25KVA-2500 KVA and voltage levels up to 6.3-11-20-36 kV. Quality production with modern technology and our expert staff.

Transformer Sales

Transformer sales and distribution in domestic and foreign markets. Customer satisfaction-oriented after-sales services.

Transformer Maintenance

Maintenance, repair and technical service services of installed transformers. 24/7 technical support and emergency intervention.